ONSITE TESTING FOR REBAR AND ANCHORS

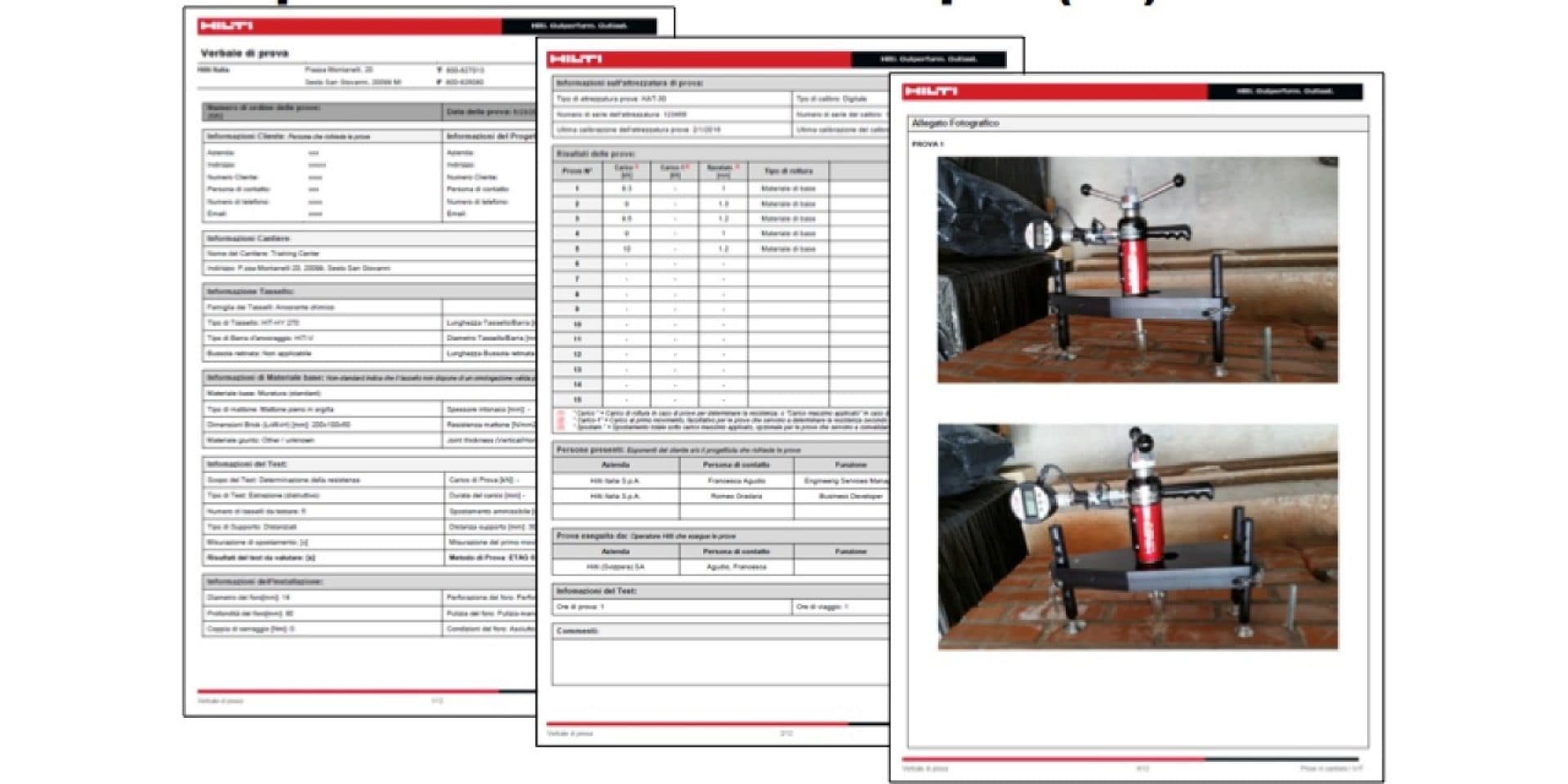

Hilti's onsite tests for post-installed rebar and fastenings

Onsite testing during design phase

During the design phase – determine the resistance of a base material and which fastening system to use.

Onsite testing after installation

After installing anchor systems – determine quality and safety. This can be required by building owners or to ensure compliance to local guidelines.

WHAT DO I GET AFTER ONSITE TESTING